Homemade metal lathe plans in PDF format offer a fantastic opportunity for individuals to create their own precision machine tools. These plans often provide detailed instructions‚ diagrams‚ and material lists‚ making it easier for even novice machinists to build their own lathe. Whether you’re looking to save money‚ customize a lathe to your specific needs‚ or simply enjoy the satisfaction of building something from scratch‚ homemade metal lathe plans are a valuable resource.

Introduction

The allure of creating your own metal lathe from scratch is a captivating prospect for many enthusiasts. The idea of building a precision machine tool‚ capable of turning and shaping metal with remarkable accuracy‚ is a testament to the ingenuity and resourcefulness of DIYers. This pursuit is not just about saving money; it’s about embarking on a journey of discovery‚ learning‚ and craftsmanship. Homemade metal lathe plans‚ often available in PDF format‚ serve as your guide through this exhilarating adventure.

These plans‚ meticulously crafted by experienced machinists and hobbyists‚ provide a blueprint for constructing a functional and reliable metal lathe. They offer a detailed breakdown of the components‚ dimensions‚ materials‚ and assembly steps‚ enabling you to bring your vision to life. Whether you’re a seasoned metalworker or a curious beginner‚ these plans offer a structured approach to building a valuable tool for your workshop.

The journey of building a homemade metal lathe is not without its challenges. It requires careful planning‚ precision‚ and a willingness to learn. However‚ the rewards are immense. You’ll gain a deep understanding of the mechanics of a lathe‚ develop valuable skills in metalworking‚ and have the satisfaction of creating a tool that reflects your own ingenuity.

Benefits of Building a Homemade Metal Lathe

Embarking on the journey of building a homemade metal lathe from plans offers a plethora of advantages that extend beyond mere cost savings. The process itself is an enriching experience‚ fostering a deeper understanding of machine tools and their intricate workings. This knowledge translates into greater confidence and proficiency when using your custom-built lathe‚ allowing you to tackle more complex projects with precision and assurance.

Furthermore‚ building a homemade lathe grants you the freedom to tailor it to your specific needs and preferences. You can choose the size‚ features‚ and capabilities that align perfectly with your workshop’s requirements. This customization ensures that your lathe is a perfect fit for your projects‚ maximizing its utility and efficiency.

Beyond the practical benefits‚ the sense of accomplishment that comes with building a functional metal lathe is unparalleled. The journey from blueprints to a working machine is a rewarding one‚ instilling a profound sense of pride in your creation. This accomplishment fosters a deeper appreciation for the craftsmanship and ingenuity involved in creating such a sophisticated tool.

Essential Components of a Metal Lathe

A metal lathe‚ whether homemade or commercially manufactured‚ comprises several crucial components that work in unison to achieve precise metalworking tasks. The headstock‚ the heart of the lathe‚ houses the motor and spindle‚ which rotates the workpiece. The tailstock‚ positioned at the opposite end of the bed‚ provides support for the workpiece and allows for drilling and other operations. The bed‚ a rigid foundation‚ supports the headstock‚ tailstock‚ and carriage.

The carriage‚ a movable assembly‚ holds the cutting tools and traverses along the bed‚ enabling precise longitudinal and cross-feeding. The cross-slide‚ a part of the carriage‚ allows for transverse movement of the cutting tool‚ enabling operations such as facing and turning diameters. The compound slide‚ also part of the carriage‚ provides additional angular adjustment of the cutting tool‚ facilitating operations like taper turning and threading.

Finally‚ the chuck‚ a device that securely holds the workpiece‚ is essential for rotating the material during machining. These components‚ working in harmony‚ enable the metal lathe to perform a wide range of operations‚ from simple turning to complex threading and shaping.

Materials and Tools Needed

Building a homemade metal lathe requires a combination of materials and tools‚ some of which you may already have in your workshop. The primary materials typically include steel for the bed‚ headstock‚ tailstock‚ and carriage‚ along with aluminum or cast iron for specific components. You may also need various fasteners‚ such as bolts‚ nuts‚ and screws‚ as well as bearings for smooth rotation.

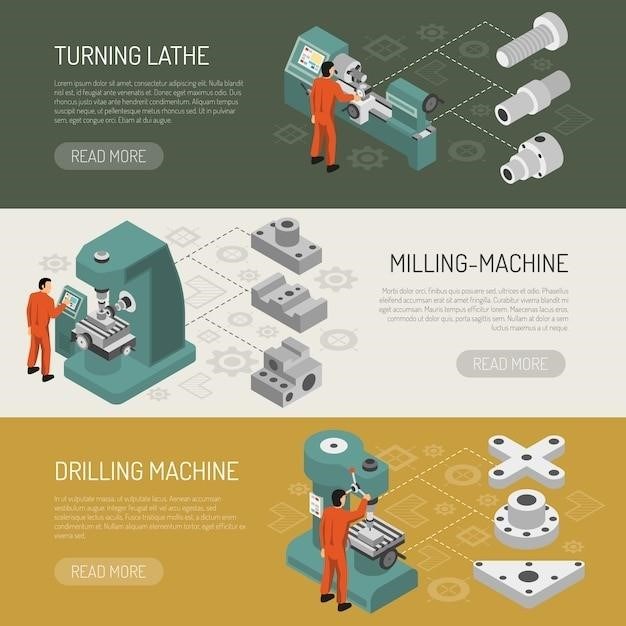

Essential tools for this project include a welding machine for joining metal components‚ a grinder for shaping and finishing‚ a drill press for creating holes‚ and a cutting torch for preparing metal pieces. Hand tools‚ such as hammers‚ wrenches‚ and screwdrivers‚ are also indispensable. While some plans may call for specialized equipment like a milling machine or lathe for specific tasks‚ many designs can be built using basic workshop tools.

Remember to prioritize safety by wearing appropriate protective gear‚ such as gloves‚ eye protection‚ and a respirator‚ when working with metal and power tools. Carefully read and follow the instructions provided in your chosen plans to ensure a safe and successful build.

Step-by-Step Guide to Building a Metal Lathe

A detailed step-by-step guide is essential for building a homemade metal lathe. These guides‚ often found in PDF format‚ provide clear instructions and diagrams to guide you through the construction process. They typically begin with preparing the materials‚ such as cutting and shaping the steel for the bed‚ headstock‚ tailstock‚ and carriage. Next‚ you’ll assemble the bed‚ ensuring it’s level and rigid‚ and then build the headstock‚ which houses the spindle and motor. The tailstock‚ used to support the workpiece‚ is assembled next‚ and the carriage‚ responsible for moving the cutting tool‚ is attached to the bed.

The guide will also detail the assembly of the cross-slide‚ which moves the cutting tool perpendicular to the workpiece‚ and the compound slide‚ which enables precise adjustments. Once all components are assembled‚ you’ll need to align the headstock and tailstock and install the motor. Finally‚ you’ll test the lathe by running it through its motions and ensuring everything is functioning correctly. It’s important to note that the specific steps involved may vary depending on the design and complexity of the lathe you’re building.

Remember to take your time‚ carefully follow the instructions‚ and don’t hesitate to seek help or clarification if needed. Building a metal lathe is a rewarding project that requires patience and attention to detail. With careful planning and execution‚ you can create a precision machine tool that will serve you well for years to come.

Safety Precautions

Safety should always be paramount when working with metalworking equipment‚ especially when building your own metal lathe. Here are some essential safety precautions to keep in mind⁚

- Wear appropriate safety gear⁚ Always wear safety glasses‚ a dust mask‚ and hearing protection when working with a metal lathe. Consider wearing gloves for added protection.

- Use a well-ventilated workspace⁚ Ensure your workspace is well-ventilated to prevent the build-up of dust and fumes.

- Secure the workpiece⁚ Always securely fasten the workpiece to the lathe to prevent it from spinning out of control.

- Avoid loose clothing or jewelry⁚ Loose clothing or jewelry can become caught in the lathe’s moving parts.

- Keep your hands away from the rotating parts⁚ Never reach for the workpiece or tools while the lathe is running.

- Use sharp‚ properly maintained cutting tools⁚ Dull or damaged tools can lead to accidents.

- Be aware of the direction of rotation⁚ Understand how the workpiece will rotate to avoid accidents.

- Take breaks⁚ Working with machinery for extended periods can lead to fatigue and accidents. Take breaks to rest your eyes and mind.

- Never operate the lathe under the influence of alcohol or drugs⁚ Always be alert and focused when working with machinery.

- Follow the instructions provided in your homemade metal lathe plans⁚ The plans will outline specific safety procedures and precautions for your particular design.

Common Mistakes to Avoid

Building a metal lathe from scratch requires meticulous attention to detail and careful planning. Here are some common mistakes to avoid⁚

- Skipping safety precautions⁚ Never underestimate the importance of safety when working with machinery. Always wear appropriate safety gear and follow the instructions in your plans.

- Using inadequate materials⁚ The materials used for the lathe’s bed‚ headstock‚ and tailstock must be strong and rigid to withstand the forces involved in turning metal. Use quality materials and avoid compromising on their strength.

- Poor alignment⁚ The lathe’s bed‚ headstock‚ and tailstock must be perfectly aligned for accurate machining. Pay close attention to alignment during the construction process and use precision measuring tools to ensure accuracy.

- Inadequate lubrication⁚ Proper lubrication is crucial to prevent wear and tear on the lathe’s moving parts. Use the appropriate lubricants for each component and apply them regularly.

- Overworking the lathe⁚ Avoid pushing the lathe beyond its capacity. Choose the appropriate cutting tools and speeds for the material you are working with to prevent damage to the lathe or your workpieces.

- Neglecting maintenance⁚ Regularly inspect and maintain your lathe to ensure it is in good working order. Clean‚ lubricate‚ and tighten components as needed.

- Rushing the process⁚ Building a metal lathe takes time and patience. Don’t rush the process and be sure to double-check your work at each stage.

Resources and Online Communities

The world of metalworking is filled with passionate individuals eager to share their knowledge and expertise. Fortunately‚ there are numerous resources and online communities dedicated to helping you build your homemade metal lathe⁚

- Online Forums⁚ Forums like “HomemadeTools.net” and “HomeShopMachinist.com” are great places to connect with other hobbyists‚ share your projects‚ ask questions‚ and find helpful advice. You can also find discussions about specific metal lathe designs and building techniques;

- YouTube Channels⁚ Search for “DIY metal lathe” on YouTube to find numerous videos showcasing building processes‚ tips‚ and tricks from experienced makers. You can also find tutorials for specific lathe designs and components.

- Blogs and Websites⁚ Many websites and blogs dedicated to metalworking‚ woodworking‚ and DIY projects offer valuable insights into building metal lathes. Look for websites that provide free plans‚ tutorials‚ and articles on lathe construction.

- Local Maker Spaces⁚ Contact your local maker spaces or community workshops. They may offer classes‚ resources‚ and access to tools that can help you with your project. You may also find fellow makers who can provide guidance and support.

- Metalworking Books and Magazines⁚ Explore books and magazines dedicated to metalworking for detailed information on lathe design‚ construction‚ and operation. You can find valuable tips‚ tricks‚ and advanced techniques from experienced machinists.

Building a homemade metal lathe can be a rewarding and fulfilling project. It allows you to create a tool that meets your specific needs and gives you a deep understanding of its mechanics. By following detailed plans and engaging with the vibrant online communities‚ you can overcome any challenges and achieve a successful outcome. Remember‚ patience‚ persistence‚ and attention to detail are key to crafting a functional and accurate metal lathe. Enjoy the journey of learning‚ experimenting‚ and realizing your vision for a custom-built precision machine tool.

Where to Find Homemade Metal Lathe Plans PDF

The internet is a treasure trove of resources for those seeking homemade metal lathe plans. Websites dedicated to DIY projects‚ maker communities‚ and even online forums are excellent starting points. Popular Mechanics‚ for instance‚ offers free downloadable plans for a small metal-turning lathe. Websites like Make⁚ Magazine showcase various projects‚ including metal lathe designs. Many individuals share their own plans and experiences through online forums‚ providing invaluable insights and support to aspiring lathe builders. Don’t hesitate to explore these online resources to discover the perfect plan for your homemade metal lathe project.