Work instructions are detailed, task-specific documents guiding employees through ISO 9001 processes. They ensure consistency, compliance, and quality, serving as essential tools within a QMS.

What Are Work Instructions?

Work instructions are detailed documents outlining specific tasks and steps within ISO 9001 processes. They break down procedures into actionable steps, ensuring consistency and compliance. Essential for achieving quality objectives.

2.1 Definition and Purpose

A work instruction is a detailed document specifying step-by-step actions for completing a task within ISO 9001 processes. Its primary purpose is to guide employees in performing tasks consistently and accurately, ensuring compliance with quality management system requirements. Work instructions are essential for standardizing operations, reducing errors, and maintaining quality standards across an organization. They serve as a practical tool for achieving operational excellence and supporting overall business objectives effectively.

2.2 Differences Between Processes, Procedures, and Work Instructions

Processes outline high-level objectives and overall business activities, while procedures detail the specific steps to achieve those objectives. Work instructions, on the other hand, provide precise, task-specific guidance for completing individual procedures. Processes are broad, procedures are intermediate, and work instructions are the most detailed. Together, they form a hierarchical structure within the QMS, ensuring clarity, consistency, and compliance with ISO 9001 standards. This distinction helps organizations maintain operational efficiency and quality across all levels.

2.3 Importance of Work Instructions in a Quality Management System (QMS)

Work instructions are vital for ensuring consistency, accuracy, and compliance in a QMS. They provide clear, step-by-step guidance, reducing errors and variability in task execution. By standardizing processes, work instructions help maintain quality, meet ISO 9001 requirements, and enhance operational efficiency. They also serve as training tools, enabling new employees to perform tasks correctly. Overall, work instructions strengthen process control, support continuous improvement, and contribute to achieving organizational quality objectives effectively.

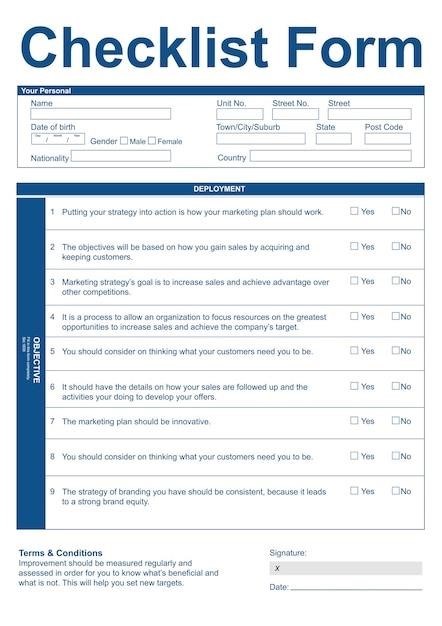

Structure of a Work Instruction

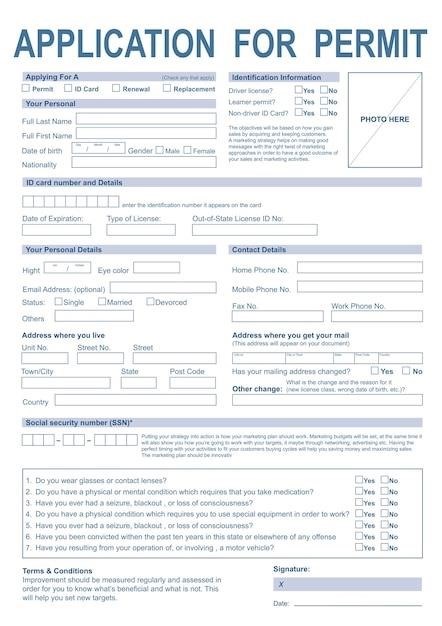

A well-structured work instruction ensures clarity and compliance, typically including sections like introduction, scope, responsibilities, step-by-step procedures, tools required, and verification methods.

The introduction section provides an overview of the work instruction, stating its purpose and relevance within the ISO 9001 QMS. It outlines the document’s scope and application, ensuring employees understand its importance and context. This section typically includes a brief description of the task or activity the instruction covers, aligning with organizational objectives and quality standards. Clear and concise language helps set expectations for the detailed steps that follow, making the instruction accessible and user-friendly.

3.2 Scope of Application

The scope of application defines the specific areas, processes, or tasks to which the work instruction applies. It clarifies the relevant departments, roles, or teams responsible for executing the instruction. This section ensures the work instruction is applied correctly and consistently across the organization. It may also outline specific conditions, limits, or exceptions, aligning the instruction with organizational objectives and ISO 9001 requirements. A well-defined scope helps prevent misunderstandings and ensures the instruction is used appropriately within the quality management system.

3.3 Responsibilities and Accountabilities

The section outlines who is responsible for creating, approving, and implementing the work instruction. It defines the roles of the quality team, department heads, and employees. This ensures accountability, compliance, and consistency in following the instruction. Clear responsibilities prevent errors and maintain quality standards. Accountability extends to adherence to the procedure, record-keeping, and continuous improvement. This alignment with ISO 9001 standards ensures effective process control and quality management system integrity.

3.4 Step-by-Step Procedures

This section provides a detailed, sequential breakdown of tasks required to complete the process. Each step is clear, concise, and actionable, ensuring consistency and accuracy. Visual aids like diagrams or flowcharts may be included to enhance understanding. The procedures align with ISO 9001 standards, promoting quality and compliance. Employees follow these steps to achieve desired outcomes, reducing errors and variability. The instructions are practical, specific, and easy to execute, ensuring tasks are performed correctly every time.

3.5 Tools, Equipment, and Resources Required

This section lists all necessary tools, equipment, and resources for completing the task. It specifies hardware, software, materials, and personnel required. Each item is described with its purpose and specifications. The list ensures employees have everything needed to perform tasks effectively. Compliance with ISO 9001 standards is maintained by verifying the availability and calibration of equipment. This section also includes links to training materials or guides for proper tool usage, ensuring tasks are executed safely and efficiently. Proper resources are essential for achieving consistent and high-quality results.

3.6 Verification and Record-Keeping

This section outlines the methods for verifying task completion and maintaining accurate records. It specifies checks to ensure each step is correctly performed and documented. Records include completion dates, personnel involved, and any deviations. Verification ensures compliance with ISO 9001 standards. Detailed documentation supports traceability and accountability. Proper storage and retrieval processes are defined to maintain record integrity. Regular audits ensure records are accurate and up-to-date. This step is crucial for demonstrating compliance during ISO 9001 audits and for continuous improvement initiatives. Effective record-keeping supports operational transparency and accountability;

Key Elements of an Effective Work Instruction

Clear language, precision, and alignment with ISO 9001 standards are essential. Visual aids enhance understanding, ensuring tasks are performed consistently and correctly. Compliance is prioritized.

4.1 Clarity and Precision

Clarity and precision are vital in work instructions to ensure tasks are performed accurately. Use simple, jargon-free language and avoid ambiguity. Specific details guide employees effectively, reducing errors and enhancing compliance with ISO 9001 standards. Clear instructions prevent misinterpretation, ensuring consistency across operations. Additionally, precise steps and unambiguous terminology help employees understand expectations, promoting quality outcomes and adherence to established processes.

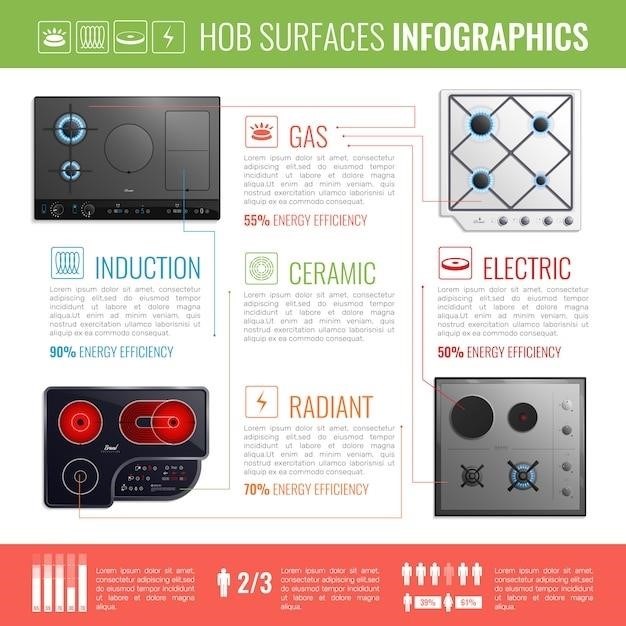

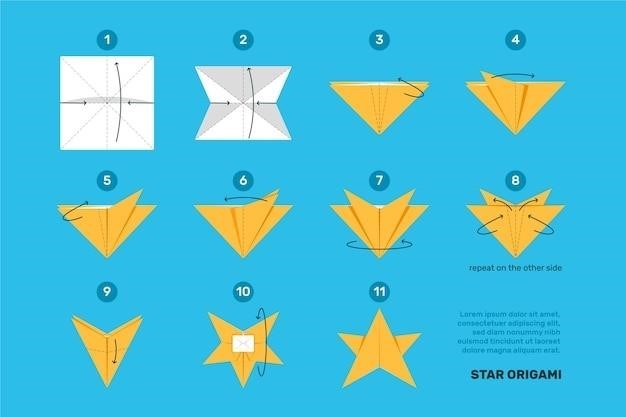

4.2 Use of Visual Aids and Diagrams

Visual aids and diagrams enhance the clarity of work instructions by providing a graphical representation of tasks. Flowcharts, images, and step-by-step diagrams help employees understand complex procedures. These tools reduce ambiguity, making instructions more accessible, especially for visual learners. Incorporating visuals ensures that processes are followed consistently, minimizing errors. Additionally, diagrams can illustrate tools, equipment, or resources required, aligning with ISO 9001 standards. This approach improves comprehension and compliance, ensuring tasks are executed efficiently and effectively across the organization.

4.3 Compliance with ISO 9001 Standards

Work instructions must align with ISO 9001 standards to ensure compliance and effectiveness within a Quality Management System (QMS). They should be designed to meet specific requirements, such as document control, versioning, and audit preparedness. Compliance ensures that tasks are performed consistently and correctly, adhering to quality objectives. By following ISO 9001 guidelines, work instructions help organizations demonstrate conformity during audits and maintain a robust QMS. This alignment also supports continuous improvement, a core principle of ISO 9001, by providing clear, actionable steps for process execution and monitoring.

How to Create a Work Instruction

Developing work instructions involves identifying needs, engaging stakeholders, and outlining clear, actionable steps. Ensure precision, compliance with ISO 9001, and thorough review before final approval.

5.1 Identifying the Need for a Work Instruction

Identifying the need for a work instruction begins with analyzing processes and tasks that require detailed guidance. This is crucial for repetitive or complex activities where consistency is key. Assess existing procedures to determine if a work instruction is necessary to bridge gaps or clarify steps. Consider feedback from employees, quality audits, or non-conformities that highlight areas needing clearer guidance. Aligning the need with ISO 9001 requirements ensures the instruction supports the QMS and enhances process control. Proper identification ensures the work instruction addresses specific tasks effectively.

5.2 Involving Relevant Stakeholders

Involving relevant stakeholders is crucial for creating effective work instructions. Collaborate with process owners, employees, and quality teams to ensure the instructions are practical and aligned with ISO 9001. Stakeholders provide valuable insights, helping to identify critical steps and potential risks. Their input ensures the instructions are clear, accurate, and applicable to real-world scenarios. This collaboration also fosters acceptance and adherence among employees. By engaging stakeholders early, you can address ambiguities and ensure the work instruction meets organizational and quality standards effectively.

5.3 Writing the Instruction

When writing a work instruction, focus on clarity and simplicity. Use clear, concise language and avoid jargon. Break down tasks into sequential, easy-to-follow steps. Include visual aids like diagrams or screenshots to enhance understanding. Ensure the instruction aligns with ISO 9001 requirements and refers to related procedures or documents. Specify tools, materials, and safety precautions needed. Define verification steps to confirm task completion. Use active voice and present tense for consistency. Ensure the instruction is free from ambiguity, making it easy for employees to execute tasks accurately and consistently.

5.4 Review and Approval Process

The review and approval process ensures work instructions are accurate and effective. Submit the draft to relevant stakeholders, including subject matter experts and supervisors, for feedback. Incorporate suggested changes and revise the document. Once finalized, obtain formal approval from authorized personnel. Document the approval date and version number. Maintain a record of approvals for audit purposes. Ensure the approved instruction is accessible to all relevant staff and archived properly. This step guarantees compliance with ISO 9001 and maintains process integrity.

Implementing Work Instructions in the Organization

Implementing work instructions involves training employees, ensuring accessibility, and monitoring compliance. This ensures tasks are performed consistently and align with ISO 9001 standards.

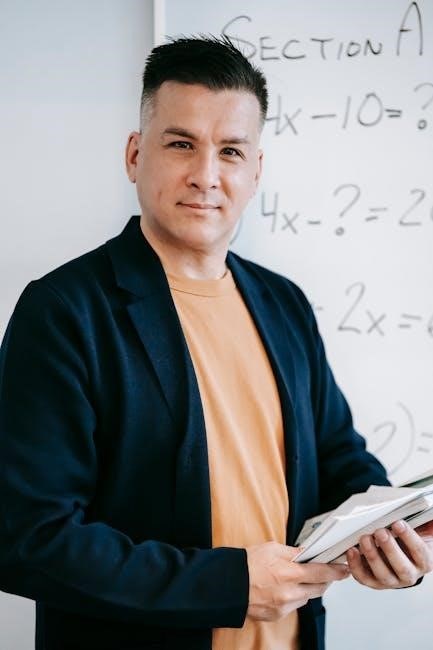

6.1 Training Employees

Training employees on work instructions is crucial for ensuring tasks are performed correctly. Hands-on sessions and interactive workshops help employees understand procedures. Regular updates on changes maintain compliance. Feedback mechanisms ensure clarity and address doubts promptly, fostering a culture of continuous improvement and alignment with ISO 9001 standards;

6.2 Ensuring Accessibility and Understanding

Ensuring accessibility and understanding of work instructions is vital for effective implementation. Clear language and visual aids simplify complex tasks. Instructions should be readily available in accessible formats, such as digital versions for easy reference. Regular reviews ensure content remains relevant and accurate, while employee feedback helps identify areas for improvement. This fosters a culture of clarity and engagement, aligning with ISO 9001 requirements for a robust QMS.

6.3 Monitoring Compliance

Monitoring compliance ensures that work instructions are followed consistently and effectively. Regular audits and checks are conducted to verify adherence to ISO 9001 standards. Documentation of processes and outcomes provides evidence of compliance. Employees are expected to understand their roles in maintaining process control. Any deviations are addressed promptly to prevent non-conformities. Continuous monitoring fosters a culture of accountability and ensures that the quality management system remains robust and aligned with organizational goals.

Maintaining and Updating Work Instructions

Regular reviews and audits ensure work instructions stay relevant. Updates reflect process changes, maintaining compliance. Document control systems manage versions, preventing obsolete instructions from being used.

7.1 Regular Reviews and Audits

Regular reviews and audits of work instructions are crucial for ensuring accuracy and relevance. These activities help identify outdated information, gaps in procedures, and areas for improvement. During audits, compliance with ISO 9001 standards is verified. Reviews involve stakeholders to gather feedback and implement necessary updates. This process ensures that work instructions remain aligned with organizational goals and quality objectives. Consistent updates prevent the use of obsolete instructions, maintaining process integrity and effectiveness across the organization.

7.2 Updating to Reflect Process Changes

Updating work instructions to reflect process changes ensures they remain relevant and effective. Whenever procedures, tools, or responsibilities evolve, instructions must be revised to match. This involves incorporating feedback, new requirements, or technological advancements. A systematic approach, including stakeholder input, guarantees clarity and accuracy. Updates should be documented, approved, and communicated to all relevant personnel. This ensures continuity, prevents errors, and maintains compliance with ISO 9001 standards. Regular updates also help in aligning work instructions with organizational goals and quality objectives.

7.3 Document Control and Versioning

Document control ensures that work instructions are managed systematically, from creation to obsolescence. Versioning tracks changes, preventing confusion and ensuring only approved versions are used. Each update is assigned a unique identifier, such as a version number or date, to maintain clarity. Archived versions are retained for audit purposes, while outdated documents are withdrawn from circulation. This process guarantees that employees always follow the latest, compliant procedures, supporting ISO 9001 requirements and maintaining consistency across the organization.

Common Mistakes to Avoid

Common mistakes include using overly complex language, lacking specificity, and inadequate training. These errors can lead to confusion, non-compliance, and inefficiency in ISO 9001 work instructions.

8.1 Overly Complex Language

Using overly complex language in work instructions can lead to confusion and misinterpretation among employees. This mistake often results in errors, inefficiencies, and potential non-compliance with ISO 9001 standards. Simplifying language ensures clarity and accessibility for all staff, regardless of their expertise level. Avoiding jargon and technical terms that may not be universally understood is crucial. Instead, focus on clear, concise, and unambiguous instructions. Additionally, incorporating visual aids or diagrams can help clarify complex steps, making the instructions more effective and easier to follow for everyone involved in the process.

8.2 Lack of Specificity

Lack of specificity in work instructions is a common mistake that can lead to variability in task execution. Vague instructions often result in misinterpretation, errors, and non-compliance with ISO 9001 standards. To avoid this, instructions should be precise, detailing exact steps, required tools, and expected outcomes. Including measurable criteria and acceptance standards ensures clarity. Ambiguity in language or procedures should be eliminated to prevent confusion. Regular reviews and updates can help maintain the instructions’ relevance and specificity, ensuring they remain effective and aligned with quality management system requirements.

8.3 Inadequate Training

Inadequate training is a significant issue that can render work instructions ineffective. Employees may not fully understand the steps or requirements outlined in the instructions, leading to errors and inefficiency. Proper training ensures that staff can execute tasks correctly, aligning with ISO 9001 standards. Regular training sessions, hands-on practice, and feedback mechanisms are essential to address knowledge gaps; Without adequate training, even the most well-structured work instructions may fail to achieve their intended purpose, potentially leading to non-compliance and quality issues within the organization.

Best Practices for Work Instructions

Best practices for work instructions include using clear, simple language, aligning with ISO 9001 standards, and incorporating visual aids for enhanced understanding and compliance.

9.1 Use of Simple and Clear Language

Using simple and clear language in work instructions ensures that all employees can understand the tasks without confusion. Avoiding complex jargon or overly technical terms makes the instructions accessible to everyone. Clarity helps in reducing errors and ensures compliance with ISO 9001 standards. Concise language also promotes efficiency, as employees can quickly grasp the steps required. This approach fosters a culture of precision and accountability, making the quality management system more effective. Clear communication is key to achieving consistent and high-quality outcomes across the organization.

9.2 Incorporating Feedback from Employees

Incorporating feedback from employees enhances the effectiveness of work instructions. Frontline workers often have valuable insights into processes, which can improve clarity and relevance. Encouraging their input fosters ownership and engagement, ensuring the instructions are practical and user-friendly. This collaborative approach aligns with ISO 9001 principles by promoting continuous improvement. Regularly seeking and implementing feedback demonstrates a commitment to ongoing refinement, leading to better process control and overall quality management system performance. It also strengthens employee involvement in achieving organizational goals.

9.3 Aligning with ISO 9001 Requirements

Aligning work instructions with ISO 9001 requirements ensures compliance and effectiveness. These documents must reflect the standard’s emphasis on clear documentation, process control, and continuous improvement. By integrating ISO 9001 principles, work instructions help demonstrate compliance during audits, ensuring consistency and adherence to quality management practices. They also serve as evidence of a well-structured QMS, supporting the organization’s commitment to meeting international quality standards and customer expectations. Proper alignment enhances traceability and accountability, making the QMS robust and reliable.

Role of Work Instructions in ISO 9001 Audits

Work instructions play a critical role in ISO 9001 audits by providing clear evidence of process control and compliance. They demonstrate adherence to quality standards.

10.1 Demonstrating Compliance

Work instructions are vital for demonstrating compliance during ISO 9001 audits. They provide clear evidence that tasks are performed in accordance with established quality standards. By following detailed steps, employees ensure traceability and accountability, which auditors require. These documents also verify that processes align with ISO 9001 requirements, showcasing a structured approach to maintaining quality. Effective work instructions help organizations pass audits by proving consistent adherence to regulatory expectations and internal procedures, ensuring operational integrity and certification readiness.

10.2 Providing Evidence of Process Control

Work instructions serve as critical evidence of process control within ISO 9001 systems. They document each step, ensuring tasks are executed consistently and correctly. By detailing responsibilities, tools, and verification methods, these instructions demonstrate a structured approach to maintaining process integrity. Auditors rely on this documentation to confirm that processes are controlled, repeatable, and aligned with quality objectives. Well-drafted work instructions provide a clear audit trail, showcasing operational discipline and adherence to ISO 9001 requirements, thereby supporting organizational compliance and continuous improvement efforts effectively.