Cataclysm Classic cooking offers a unique path to gold and self-sufficiency. It’s a secondary profession, easily paired with others, and heavily reliant on daily quests for efficient leveling.

Why Cooking Matters in Cata Classic

Cooking in Cataclysm Classic isn’t just about providing food; it’s a surprisingly lucrative and essential profession. The daily cooking quests, fondly remembered by players, are a cornerstone of leveling and provide substantial rewards. Unlike primary professions, cooking doesn’t demand you sacrifice a gathering or crafting slot, making it incredibly accessible.

Beyond the quests, crafted food offers significant benefits for raiding, dungeons, and PvP. Consumables provide vital stat boosts and healing, enhancing performance. Furthermore, many recipes are in high demand on the Auction House, offering a consistent gold income. Players appreciate the ability to create self-sufficiency, reducing reliance on external sources for essential consumables. Even hardcore characters benefit from the consistent resource gains from cooking and fishing.

Cooking as a Secondary Profession

Cooking’s strength lies in its classification as a secondary profession. This means it doesn’t compete with your two primary professions – crafting and gathering – allowing for a versatile character build. Unlike professions like Alchemy or Enchanting, you won’t need to drop a core skill to pursue culinary mastery. This flexibility is particularly appealing to players aiming for self-sufficiency without compromising their main income streams.

Pairing cooking with professions like Fishing is a natural synergy, providing a readily available source of ingredients. It’s often recommended for hardcore characters due to the consistent resource gains. While professions like Archaeology also fall into the secondary category, cooking offers more consistent and immediately useful benefits, especially regarding consumables for personal use and auction house sales. It’s a low-pressure profession that rewards consistent effort.

Leveling Cooking: A Comprehensive Guide

Efficiently leveling cooking in Cata Classic involves distinct phases: Old World recipes to 300, Cataclysm recipes to 350, and then focusing heavily on daily quests.

1-300 Cooking: Old World Recipes

Reaching level 300 in cooking primarily utilizes recipes from the original World of Warcraft and The Burning Crusade. This initial phase is relatively straightforward, though can be time-consuming. Focus on readily available ingredients from vendors and early-game zones. Many players report having 174/300 skill points in Old World Recipes at level 85, indicating progress can be made even while leveling through expansions.

Prioritize recipes with high skill-up chances and low material costs. Simple dishes like Baked Salmon, Seasoned Wolf Steaks, and various stews are excellent choices. Remember that skill gains diminish as you approach the next level, so you may need to switch to more challenging recipes as you get closer to 300. Don’t be discouraged if you encounter a skill-up block; persistence and variety are key. It’s also worth noting that some players experience issues with Old World Recipes not displaying correctly, potentially requiring a UI reset.

300-350 Cooking: Cataclysm Recipes

Transitioning past 300 requires embracing the new recipes introduced in the Cataclysm expansion. This is where leveling can become more focused, as many ingredients are specific to the new zones. Players often find themselves starting at 11/75 skill in Cataclysm Cooking upon reaching level 85, highlighting the need to actively pursue these recipes.

Initially, focus on recipes utilizing ingredients readily available in Mount Hyjal, Vashj’ir, and Deepholm. Look for recipes that offer a good balance between skill-up potential and ingredient accessibility. Be aware that some Cataclysm recipes require fishing, potentially making Fishing a valuable complementary profession. It’s crucial to actively seek out these new recipes, as simply continuing with Old World recipes will yield minimal progress. This phase bridges the gap to the more rewarding daily quest system.

350-450 Cooking: Focusing on Daily Quests

Reaching 350 Cooking unlocks the true power leveling potential: daily cooking quests. These quests, often found in zones originally from The Burning Crusade (TBC), are the most efficient way to gain skill points. A key aspect is that these zones don’t allow for flying, adding a layer of time management to the process.

The daily quests consistently provide substantial skill gains and valuable rewards. Prioritize completing these quests daily to maximize your progress. Remember that the quests require specific recipes and ingredients, so preparation is key. Many players fondly recall the dedication required for these dailies, making them a core part of the Cata Classic cooking experience. Efficient route planning and ingredient gathering are vital for optimal leveling during this phase.

Daily Cooking Quests: The Heart of Cata Cooking

Daily cooking quests are central to leveling in Cataclysm Classic. They’re primarily located in TBC-era zones, offering consistent skill gains and valuable rewards for dedicated cooks.

Understanding Daily Quest Zones (TBC Tagged)

A key aspect of maximizing your cooking level in Cataclysm Classic revolves around understanding the daily quest zones. These zones are notably tagged as The Burning Crusade (TBC) content, which introduces a specific limitation: flight is unavailable within these areas. This means players must navigate on foot or utilize ground mounts, impacting quest completion time and efficiency.

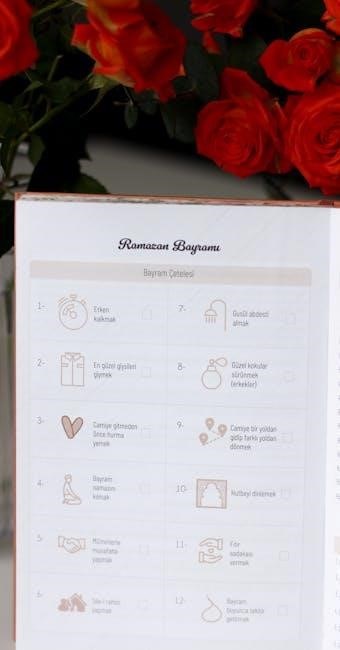

Common zones for cooking dailies include areas like Terokkar Forest, Nagrand, and Shadowmoon Valley. Each day, different NPCs within these zones will offer cooking-related quests, typically requiring the delivery of specific crafted items. The quests rotate, ensuring variety and preventing monotony. Remember to check all available NPCs in each zone daily to ensure you complete all available quests. Planning your route efficiently, considering the lack of flying, is crucial for maximizing your daily gains.

Being aware of this TBC tagging is vital for planning your cooking routine and optimizing your time investment. It’s a core element of the Cata Classic cooking experience.

Maximizing Daily Quest Efficiency

To truly excel at leveling cooking in Cataclysm Classic, efficient daily quest completion is paramount. Pre-planning is key: gather all necessary ingredients before starting your daily route. Utilize the Auction House to acquire materials you don’t have, comparing prices to ensure cost-effectiveness. Consider stocking up during off-peak hours for better deals.

Optimize your route within each TBC-tagged zone. Since flying is disabled, map out the most direct path between quest givers. Grouping quests geographically will save significant travel time. Having a fast ground mount is also highly recommended.

Furthermore, consider utilizing cooking-specific addons that track daily quest availability and ingredient costs. Finally, remember that consistent daily completion is more valuable than sporadic bursts of activity. A steady, optimized routine will yield the fastest results.

Rewards from Daily Cooking Quests

Daily cooking quests in Cataclysm Classic provide a substantial boost to skill progression, far exceeding what traditional recipe grinding offers. Beyond the significant cooking skill points gained with each completion, these quests reward players with valuable gold. This income stream can help offset the cost of ingredients and other profession expenses.

Importantly, daily quests frequently award cooking-specific tokens. These tokens are crucial for purchasing unique recipes, often those highly sought after on the Auction House. Some quests also offer a chance to obtain rare ingredients, further enhancing your profitability.

Don’t underestimate the reputation gains associated with these dailies. Increased reputation with the relevant factions unlocks access to additional recipes and rewards, solidifying your position as a skilled Cata Classic cook.

Essential Cataclysm Cooking Recipes

Cata Classic cooking features recipes vital for raiding, dungeons, and PvP. Mastering high-demand Auction House items, alongside beneficial consumables, maximizes profit and player utility;

High-Demand Auction House Recipes

Maximizing profit in Cataclysm Classic hinges on identifying and consistently crafting recipes with high auction house demand. Several stand out as reliable gold-makers. Spicy Scorpion Stew, requiring Scorpion Peels readily available in Uldum, consistently sells well due to its use in raiding and dungeon content. Similarly, Blackened Dragonfin, utilizing Dragonfin Angelfish, is a popular choice for players seeking stat boosts.

Don’t overlook the value of elemental-themed foods like Fire-Poached Salmon or Frost-Rimmed Cod, often sought after by players gearing for specific encounters. Regularly monitoring auction house prices is crucial; adjust your crafting focus based on current market trends. Investing time in gathering the necessary ingredients yourself, particularly through fishing or farming, can significantly increase your profit margins. Remember to consider server population and competition when determining pricing strategies.

Recipes for Raiding and Dungeons

Successful raiding and dungeon runs in Cataclysm Classic often depend on consumable buffs, making specific cooking recipes highly valuable. Chief among these are stat-boosting foods like Blackened Dragonfin, providing a significant increase to critical strike rating, favored by DPS classes. For tanks and healers, foods offering stamina and spirit regeneration, such as Seasoned Wolpertinger, are essential for survivability.

Rumbleweed Family Stew, offering a well-rounded stat boost, is a versatile option suitable for various roles. Consider the encounter’s demands when choosing recipes; some fights benefit more from haste, while others prioritize critical strike or mastery. Stocking up on these recipes and selling them to raid groups can also generate substantial gold. Prioritize recipes requiring readily available ingredients to ensure a consistent supply for yourself and potential buyers.

Recipes for PvP

Player versus Player combat in Cataclysm Classic benefits greatly from strategic consumable usage, and cooking plays a vital role. Recipes providing stamina regeneration are paramount, allowing for prolonged engagements and quicker recovery between fights. Spiced Salmon, for example, offers a substantial stamina boost, crucial for surviving burst damage.

For classes reliant on mana or energy, foods offering spirit or increased resource regeneration, like Crunchy Spider Surprise, can be game-changers. Consider recipes that provide a small, consistent benefit rather than a large, short-lived one, as sustained advantages are often more impactful in PvP. Auctioning PvP-focused recipes can also be profitable, as players consistently seek consumables to enhance their performance in Arenas and Battlegrounds. Remember to check current meta builds to identify the most sought-after stat boosts.

Troubleshooting Common Cooking Issues

Cooking issues often arise from skill point confusion or recipe availability. Players report being stuck at level 1, or old world recipes not appearing correctly.

Stuck at Cooking Level 1

Encountering a roadblock at cooking level 1 is a surprisingly common issue in Cataclysm Classic. This typically happens when players are attempting to use “Cataclysm Cooking” recipes directly after starting the profession at level 85. The system often defaults to showing only these recipes initially, but they don’t contribute to your overall cooking skill.

To resolve this, you need to specifically focus on Old World recipes. Open your cooking window (usually with the ‘K’ key) and ensure you’re selecting recipes from the “Cooking” tab, not “Cataclysm Cooking.” Even if the skill requirements seem low, crafting those older recipes is crucial for breaking past level 1.

If Old World recipes aren’t appearing, double-check that you’ve learned them from cooking trainers in major cities. Sometimes a trainer visit is required to unlock the initial recipe list. Remember, consistent crafting of appropriate-level recipes is the key to progressing beyond that frustrating starting point.

Old World Recipes Not Showing

If your Old World recipes aren’t appearing in the cooking window, despite being level 85, it indicates a potential issue with initial trainer learning or a UI glitch. First, revisit a cooking trainer in a major city – Ironforge, Orgrimmar, or Stormwind – and ensure you’ve spoken to them and learned the initial recipes. Even if you think you have, repeating the process can sometimes resolve the problem.

Next, try resetting your UI. A corrupted or outdated UI can cause display errors, preventing recipes from showing. To do this, close World of Warcraft, rename your “Interface” and “WTF” folders (located in your WoW installation directory), and then restart the game. This will reset your UI to its default settings.

Finally, double-check that you haven’t accidentally filtered your recipe list. The cooking window has filters; ensure none are active that would exclude Old World recipes. If all else fails, submitting a bug report to Blizzard may be necessary.

Resources for Cata Classic Cooking

Numerous online resources can significantly aid your journey to maxing out cooking in Cataclysm Classic. Project Paladin offers a comprehensive cooking guide, often including video tutorials and detailed leveling paths – accessible via their Discord invite link. Websites like Game Rant and Wowhead provide articles detailing profession updates and optimal strategies for earning gold through cooking.

YouTube is also a valuable source, with many content creators sharing their experiences and tips for efficient daily quest completion and recipe acquisition. Dedicated WoW Classic forums and Reddit communities (like r/wowclassic) are excellent places to ask questions, share discoveries, and learn from other players.

Don’t underestimate the power of in-game resources! Utilize the Auction House to monitor recipe prices and identify profitable items to craft. Remember to check trainer locations for new recipes as you level up.